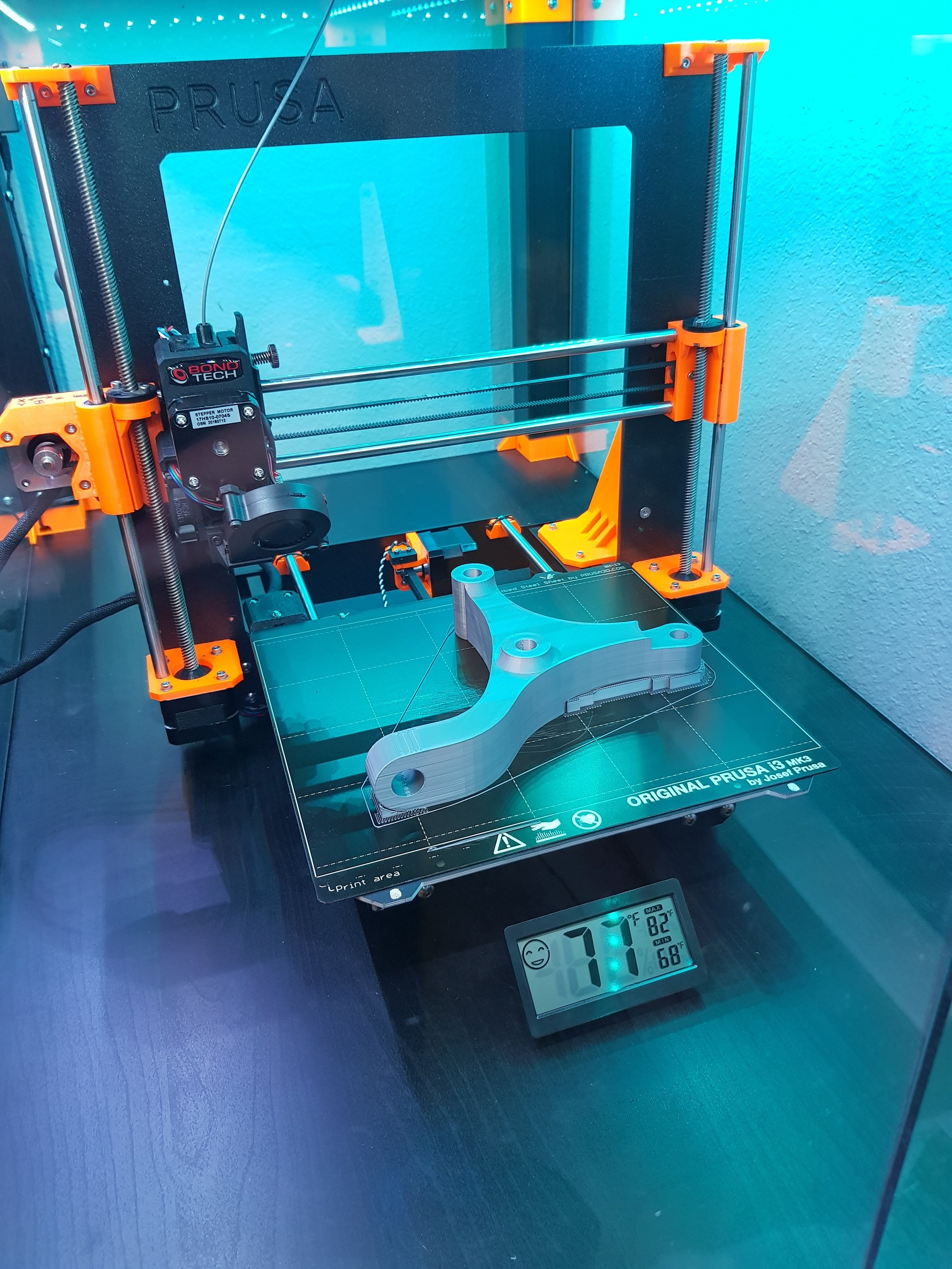

Steering Arm

A client came to us with a request to fix their bump steering issue on a custom built car. After checking the ackerman angle and cycling the suspension we found that new steering arms needed to be built to solve the problem. We used a Faro 3D scanner to scan the existing suspension and steering components then imported them into Solidworks to design a new steering arm. The arm had a stress test simulation run on it in Solidworks to solidify the design before being 3D printed and final checking done installed on the car. Now the design will be CNC machined and it saved the client time and money by only having to make one final part instead of several prototypes.